Data From Our Growers: How the LGM Stacks Up

A note to readers:

Since this article was published in 2015, we have launched our next generation container farm model, The Greenery™ S, so the content is outdated. The Greenery S has over 70% more growing space than the Leafy Green Machine! Depending on the variety and size of the crops, the Greenery S has the capacity to grow anywhere from 3,000 to almost 9,000 mature plants at one time.

Over the past few years we’ve onboarded dozens of farmers. They’re operating Leafy Green Machines across the United States and Canada in a variety of different scenarios. Some operate as a brand-new business and sell directly to customers, restaurants and wholesalers. Some are the restaurants and wholesalers. And some farmers are even corporations and universities feeding their employees or students.

With this large network of farmers growing in the LGM we’ve been able to collect a lot of data. Everything from grow times and crop yields to business expenses and produce pricing. With that, we’re now able to move away from projections and provide real-life examples of what the farm can do.

The thing is, numbers are tough. So in order to break down our farmers’ data into a way everyone may be able to relate to, we went to our CFO, Heather, to make sense of things.

Before coming to Freight Farms, Heather worked at Launch Capital and with a whole bunch of startups. She loves numbers, and I mean LOVES numbers. I’ve never seen anyone get more excited about cash flow projections in my life.

She regularly sits down with our in-house farmer, Jaime, to aggregate all our farmers’ information. To help us illustrate this data, she’s organized it in a way that is much more digestible. To make things even easier we’re breaking the information into two posts.

We’re often asked how the LGM compares to conventional farming, so here we’re tackling it from two different angles: linear growing feet and annual yields. Other questions that arise frequently are related to crop yields, business and operating costs, as well as revenue and pricing, so we’ll be following up separately with those numbers too.

The clearer these numbers are, the easier it is for people interested in becoming a freight farmer to make the decision to join us, and for our community to understand how it fits into the bigger picture. As always, please feel free to reach out with questions or comments you have. We want to hear from you!

Linear Growing Feet

Sometimes it’s hard to wrap your head around comparing vertical hydroponic growing to conventional agriculture where farmers grow horizontally in soil. To make this easier, we’re going to compare Freight Farming to conventional farming by thinking of it in linear growing feet. Something to keep in mind when comparing these methods of farming is that the LGM has the ability to grow year round, regardless of the season, whereas conventional means of farming have seasonality restrictions that limit the amount of time they’re able to grow. Here we assume that there’s a single harvest annually (per acre), because we found only 2 states (California and North Carolina) where an acre can be harvested twice per year. We also ignored any natural disasters, crop disease or animal infestation where the LGM had an unfair advantage.

The main variable that distinguishes the difference between annual linear growing capacity of the LGM and conventional farming is the number of times crops can be harvested per year. We chose to focus on one crop for this exercise, lettuce, for consistency and because we have the most data on this crop. Regardless of what our freight farmers are growing, the entire linear footage in the farm will be turned over (harvested) a minimum of 8 times per year and a maximum of 12 times per year.

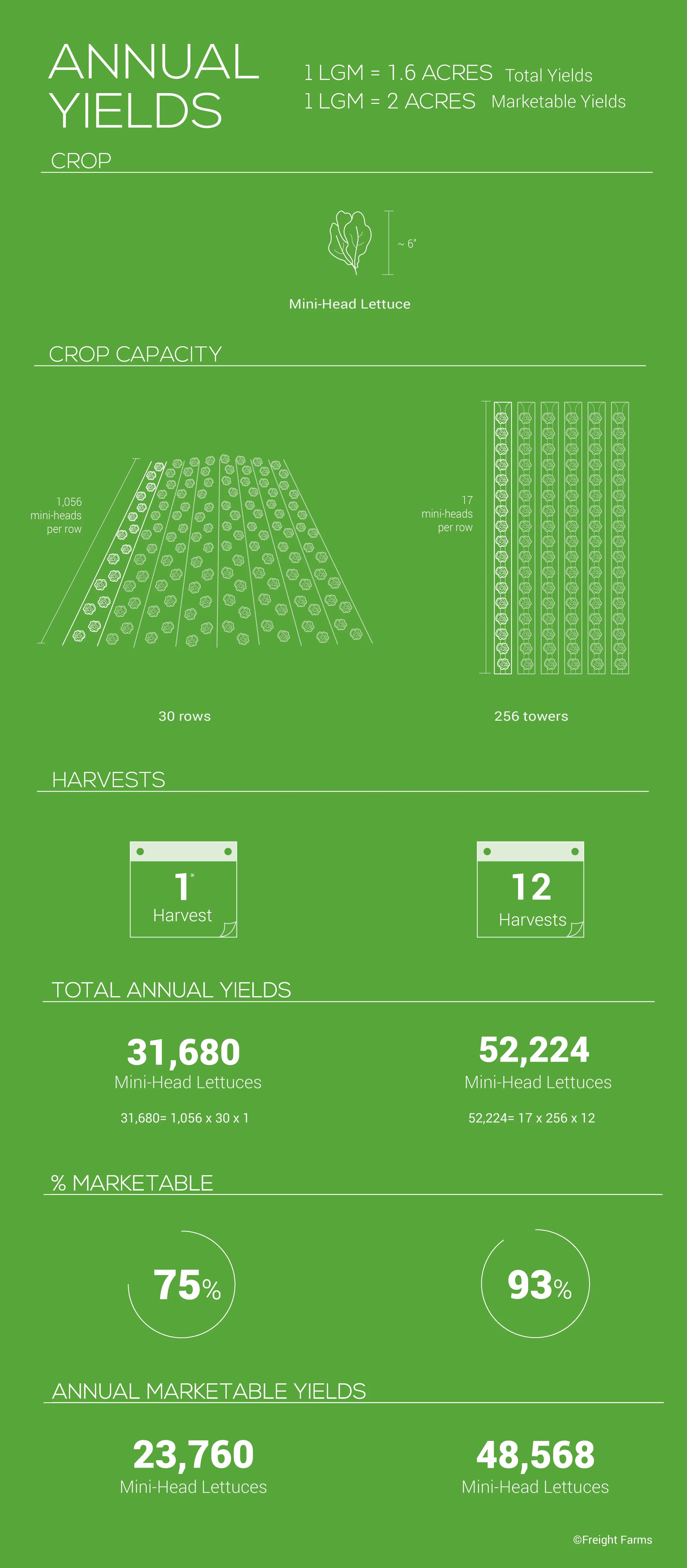

Annual Yields

This is where the numbers and context get interesting to compare. Again, we chose to stick to one crop for consistency: mini heads of lettuce. Our network of farmers has had success implementing this mini-head lettuce program, and find this crop variety to be in high demand in certain regions. When growing mini-heads of lettuce our farmers are reporting 12 full farm harvests per year, as the crop has a four week grow cycle in the vertical towers.

Here we’re comparing the annual yields of mini-head lettuce per acre grown conventionally to annual yields from one LGM. You’ll notice we’re giving two calculations. The first is using 100% of the yields of each farming method, and the second is using only the marketable percentage of yields. Typically 75% of conventionally farmed lettuce is marketable, and our farmers report that 93% of lettuce grown in the LGM is marketable.

We hope these graphics provide value for those interested in learning more about vertical farming, and help others learn more about how our farmers grow in the Leafy Green Machine. These comparisons can vary depending on the crop being grown due to a few variables like crop spacing and grow times, but for consistency we stuck with the crop we had the most data on. The data on conventional growing was gathered from both UC Davis and Washington State University studies for this exercise.