hy•dro•pon•ics

\ ˌhī-drə-ˈpä-niks \

(noun) The cultivation of plants by placing the roots in liquid nutrient solutions rather than in soil; soilless growth of plants.

Hydroponic farming is more than just another way to grow plants — the technology has the potential to change how we engage with food cultivation as a whole!

For the first time since humans started tilling the land, modern hydroponic farming technology frees us from the soil beneath our feet, allowing us to bring food production indoors where we can layer in additional climate and lighting controls. The result is an ability to grow food anytime, anywhere in the world.

Hydroponic Container Farm

The Greenery™ S is a hydroponic container farm. Unlike traditional farms, the plants in the Greenery S grow vertically indoors without soil, with the plants obtaining all their nutrition from water and their light energy from powerful LED lights. This independence from land, climate, and season allows the Greenery S to bring the power of food production in any season or climate.

The Greenery S is the most advanced vertical farming container currently available. It is able to produce up to 2.5 acres’ worth of nutritionally-dense crops such as lettuces, brassicas, herbs, leafy greens, and more.

Hydroponic Farming Systems in the Greenery S

Thanks to its sophisticated hydroponic growing systems, the Greenery S is also highly water-efficient, supporting up to 13,000 plants with approximately 5 gallons of water a day — less than the average dishwasher! The Greenery S uses these two types of hydroponic farming:

Ebb-and-Flow Hydroponic System

The Greenery S Nursery Area uses ebb-and-flow irrigation to nourish plants in their first few weeks of life. After being seeded into sponge-like peat moss grow plugs, the growing plants are moved into two horizontal troughs, where they stay through the sprout and seedling stage.

During these weeks, the plants receive nutrient-rich water on a regular schedule. The water is mixed with nutrient solutions chock-full of the minerals found in healthy soil (nitrogen, potassium, phosphorus, etc.) in a 30-gallon seedling tank. From there, the water is transported into the shallow troughs, which fill enough to saturate the roots. After a few minutes, the water is drained back into the seedling tank. It continues to recycle on a regular watering schedule.

Drip Irrigation Hydroponic System

The Greenery S Cultivation Area takes advantage of the vertical farming system and uses gravity to make drip irrigation possible. The process starts in the main tank, which holds 90 gallons of water at a time. The same nutrient-rich solution is mixed into the main tank and the enriched water is plumbed overhead, where it is released through drip emitters to the top of the Greenery S’ 88 plant panels on a regular watering schedule. As the water drips down steadily, a wicking material helps to draw the water to the plants' roots. Any water that isn’t consumed by the plants flows out the bottom of the panel into floor gutters and is then recirculated right back to the main tank.

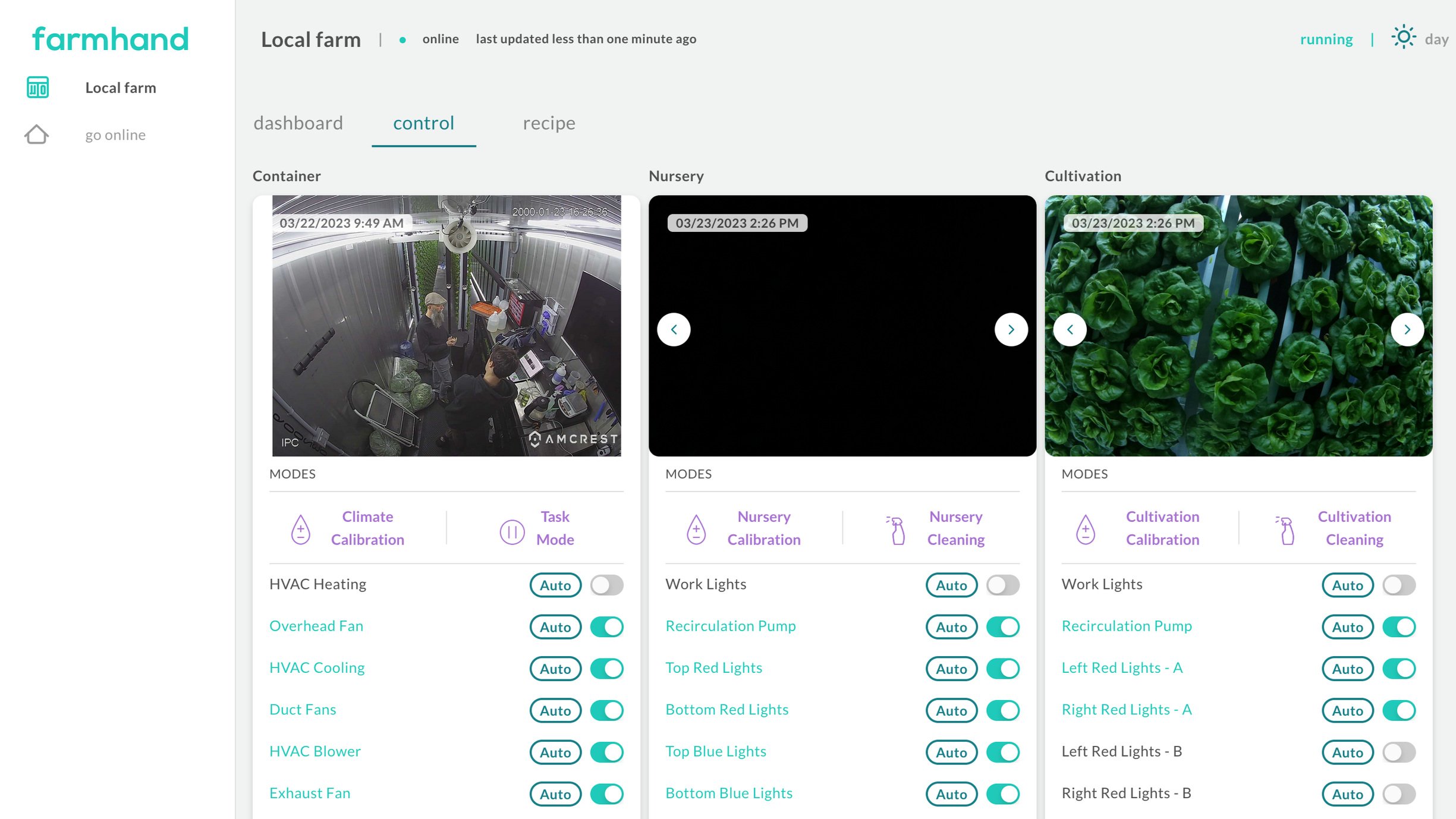

In addition to being hydroponic and vertical, the Greenery S is also a smart farm!

All of the components in the farm are linked directly to our farmhand® app through IoT sensors, which relay farm data and give the operator complete control. This is especially helpful for controlling the two hydroponic farming systems in the Greenery S. Farmhand not only automates separate watering schedules for seedlings and mature plants, but also monitors water levels in two tanks and ensures that water nutrient levels are always consistent!

Advantages of starting a hydroponic farming business

Grow Food Year-Round

With plants safe from pests and the elements, hydroponic farming allows you to grow and harvest consistently so you can always sell the freshest local food, regardless of the season.

No Experience Necessary

Hydroponic systems remove many of the variables involved in soil farming, making it easy for someone with limited farming knowledge to get involved in growing food.

Sell A High-Quality Product

Plants growing hydroponic growing systems — especially indoor ones — always have the perfect conditions, allowing them to develop beautiful structures and deep flavors.

Full Transparency & Food Safety

Hydroponics allow food to be grown closer to it’s final destination, which simplifies the food supply chain, creating better transparency and reducing risk of food-borne illness.

Create Positive Change

No matter which cause you champion — sustainability, local business development, or nutrition — hydroponic growing systems are a platform to build a business with a strong message.

Reduce Labor

Hydroponic systems require no tilling, weeding, heavy-lifting, or extensive stooping and kneeling. All you need to maintain healthy yields is regular cleaning and maintenance.

Learn more about hydroponics

+ Brief History of Hydroponics

The term “hydroponics” was coined by Dr. William Frederick Gericke in 1937. However, the practice of growing plants without soil is much older than that: the Hanging Gardens of Babylon (circa 600 BC) and the Aztecs' sixteenth-century floating gardens are all examples of hydroponic growing techniques. Basing his work on research and observations from naturalists and scientists of the past (Sir Francis Bacon, John Woodward, Julius von Sachs, and Wilhelp Knop), Gerike introduced hydroponics in their modern form. Working at UC Berkeley, Gerike developed a method of growing plants using just water and nutrients, shocking his colleagues by growing 25-foot-tall tomato vines. Since then researchers, scientists, and farmers have refined the process.

+ Benefits of Hydroponic Farming

Save water: On average, hydroponic growing systems use 90 percent less water than soil-based farming by efficiently recapturing and recycling water.

Use space wisely: A hydroponic farm can grow 3-10 times the number of crops in the same amount of space as traditional farmland.

Plants are safe: Food is typically vulnerable to extreme weather and pests. Hydroponic systems can be set up indoors, away from harmful elements.

No need for chemicals: Because food grows inside away from pests, there's no need for any harmful herbicides or pesticides.

Farm-to-table made easy: Since you can put a hydroponic farm anywhere, it's easy to shorten the distance the food ultimately travels to the plate. This means food is fresher and more nutritious when it gets eaten!

+ Other Types of Hydroponic Systems

Deep Water Culture: Plants are supported on a floating material while the roots hang below in the nutrient solution.

Aeroponics: Plant roots hang suspended in the air and are periodically misted with the nutrient solution.

Nutrient Film Technique: The nutrient solution is pumped through a channel in which the plant roots lie.

+ Other Indoor Hydroponic Farming Methods

At-Home System: This category of hydroponics includes build-it-yourself custom gardens or pre-made home-growing appliances. While home-growing is the lowest cost and lowest risk entry point to hydroponic growing, it also corresponds with lower output and is therefore best for hobbyists rather than urban agriculture entrepreneurs.

Warehouse: Warehouse hydroponic farms are a great way to turn underutilized buildings into operations that create jobs and feed communities. The large-scale operations allow farmers to automate most or all of the process, preventing the cost of production from swelling out of control. However, a warehouse growing operation must overcome high cost and infrastructure hurdles before becoming profitable.

Wondering how much it costs to ship a container farm? Learn what factors influence delivery and crane pricing - and how to avoid unexpected charges.